EPISODE:03

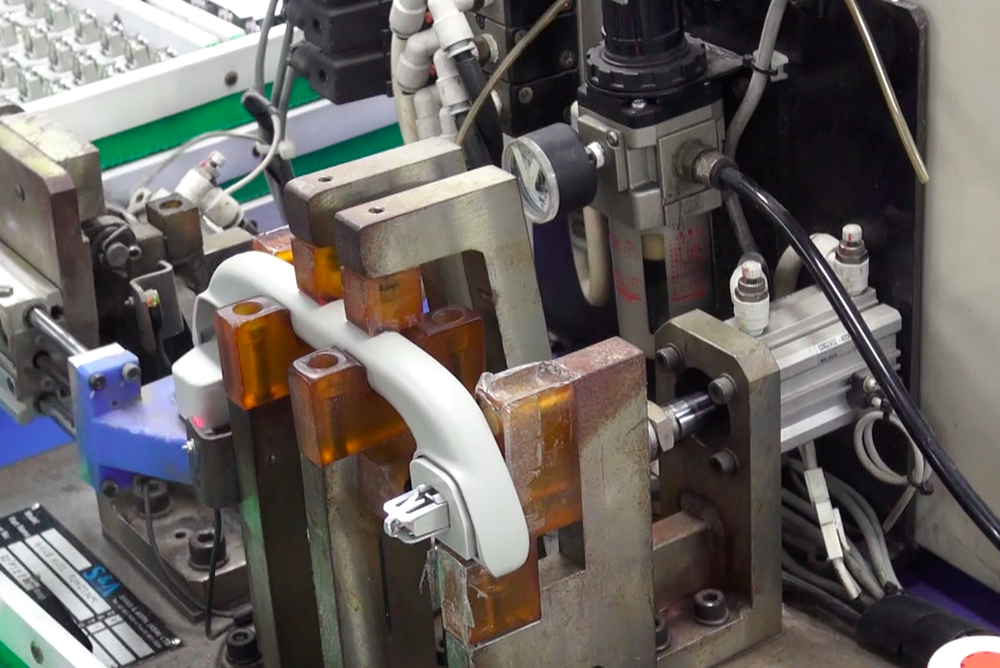

Hot press

Select materials to match the products The compounding resin are infinite

「Thermoforming」 is a molding technology to put heat a thermoplastic sheet to its softening point and formed to a specific shape in a die. Kumi Kasei produces the Trunk Side and the Fender by moldable felt which is made from polyester fiber. Features of our thermoformed products are light weight and high accoustic performance. We value our customer's requirements and design composition of materials to meet the requirements. Based on shape and application, we select number, thickness, and length of fibers to avoid "See-through" and "Tear".

Plus-one molding technology in unique ideas

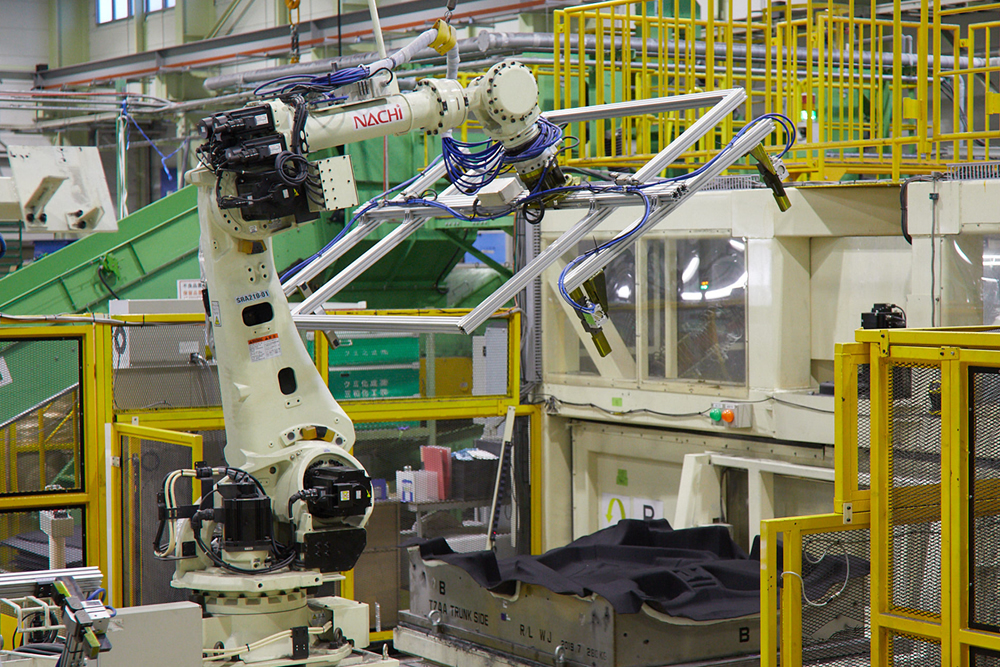

Kumi Kasei also have made efforts to develop Hybrid products which are combined injection molding technlogy and thermoforming technology. The Trunk Liner was normally produced by injection molding. We have achieved great weight reduction and kept stiffness by utlilizing moldable felt material as main wall material and, solid plastics in the areas which are required rigidity such as the trim clips attached to car body and the frame. Our technologies that we have built up over many years in plastic molding technology, is utilized in the adhesion process to assemble solid plastics and moldable felt.

Do everything possible to realize customer's needs

Moldable Felt Fender Liner that is produced by Thermoforming was developed for road noise reduction.

In addtion to expectations of weigth reduction and significant improvement in accoustic performance, it was a development challenge how to prevent an impact to driving due to buildup of snow in tire house. We collaborate with material suppliers to select composition of fibers in felt and create a water proof layer on the product to prevent buidup of snow.The product has utilized 「the Co-Creation Manufacturing」 to realize customer's needs.

Light weight and sustainable products even more

We, as a company who takes a part of the mobility industry, aim for sustanable manufacturing. Trimmed and excess material is thermal recycled via pelletizing recycle process. This is one of our activities of the sustanable manufacturing.

In the future, we strive to develop products are made of material which is recycled from trimmed and excess material, and material which is from renewable resources, and degradable in the ground. Interests of the Under the circumustances of growing the EV and improvement of fuel economy, we continue to meet customer's needs of weight reduction, and we challenge for the hybrid manufacturing of injection molding and thermoforming which can be done by only Kumi Kasei.

Episode

製品エピソード

-

Grab rail

Kumikasei's flagship products

Episode 01

We are pursuing high safety and light weight utilizing the resin material charactaristics as much as possible. -

Piano black

「Piano Black Series」 is more grossy than Piano itself.

Episode 02

The products with the deep gloss have been realized by our original patent technology 「KISS molding」 -

Hot press

It is a forming technology

Episode 03

to press the soften material by heat in the mold.

We produce the Trunk Side and the Fender.

Company

Information on company information and bases around the world. We will respond to customer requests by utilizing our domestic and overseas networks.

READ MORE »

CSR

Aiming to be a company needed by society, we are working on "sustainable manufacturing".

READ MORE »